Project Description

Ultraviolet Weathering Test Chamber can simulate the product in the sun,rain,humidity and dew conditions…….

Description

Ultraviolet Weathering Test Chamber is applicable for the sunlight resistant test of nonmetallic materials and aging test of artificial light sources. A variety of industrial products can make the reliability test, UV test chamber can simulate the product in the sun, rain, humidity and dew conditions, including damage caused by bleaching, color, brightness down, powder, crack, blur, brittle, intensity decreased and oxidation.

Application

- Paint, adhesives, resins

- Cosmetics

- Plastics

- Printing and packaging

- Aluminum

- Electronics

- Electroplating

- Metals

- Pharmaceuticals

Detailed pictures

Control panel

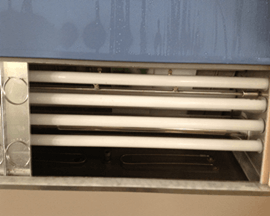

UV lamps

Specimen holder

- Working chamber corrosion resistance SUS#304 stainless steel material

- Equipped with 8pcs UV lamps(40W)

- Temperature Range RT+10℃ to 70℃

- Black Panel Temperature (BPT) 40~65℃

- TEMI880 Programmable LCD controller

- Spraying water, automatic water supply

- Equipped with 25 pieces of specimen holders

- Steam condensation exposure, radiation exposure

- With Safety protection devices

Model | JYZN-P |

Consumed Power | 5KW |

Supply Voltage | 380V 50/60HZ |

Temperature Control Range | RT+10 °C ~ +70 °C |

Black Panel Temperature | BPT 40 °C ~ 65°C |

Controller | TEMI880 LCD Touch Screen Controller |

Temp.uniformity and Fluctuation | ±3℃,1℃ |

Humidity Range | ≥95% R.H |

Internal Dimension | W450*D1170*H500MM |

Outer Dimension | W500*D1380*H1480MM |

Specimen Holder | 25 pieces |

Distance between specimen and lamp | 50±2MM |

Lamp parallel center distance | 70MM |

Light | UVA-340 or UVA-313(8PCS)-40W |

Wave Length | 315-400nm or 280-315nm |

Water Spray | Spraying water |

Protection | Over temperature,short phase,water shortage,etc. |